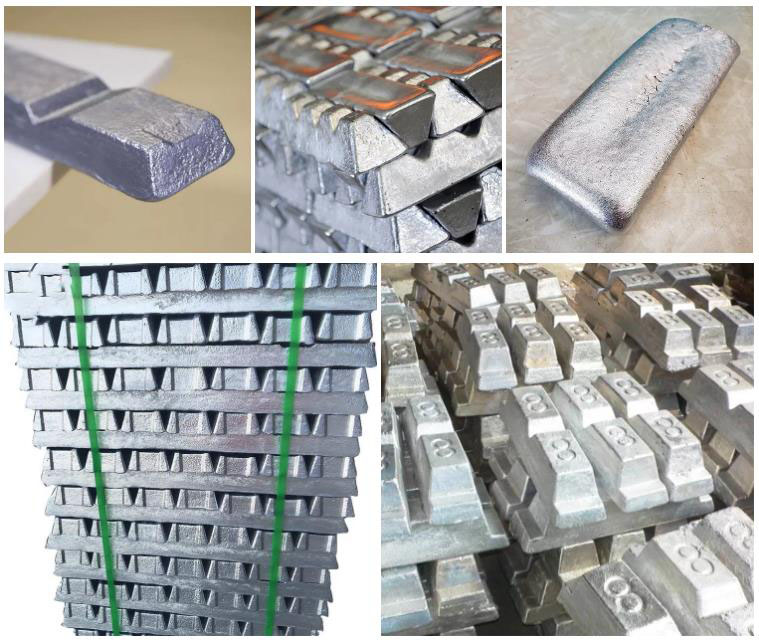

Because aluminum is light, aluminum ingots are widely used in construction, power, packaging, transportation, consumer goods and other professions. It can be used to produce packaging materials for aluminum sheet, strip and foil, aluminum alloy and anti-corrosion, and also can be used for aluminum alloy, utensils, cables, conductive bodies, central alloys, decoration materials, daily necessities, etc. in the chemical industry.

Aluminum ingot is an alloy made of pure aluminum and recycled aluminum as raw materials, and added with other elements such as silicon, copper, magnesium, iron, etc. according to international standards or special requirements to improve the castability, chemical and physical properties of pure aluminum.

After the aluminum ingots enter the industrial application, there are two categories: cast aluminum alloy and wrought aluminum alloy. Cast aluminum and aluminum alloy are aluminum castings produced by casting method; Deformed aluminum and aluminum alloy are the processed products of aluminum produced by pressure processing: plates, strips, foils, tubes, bars, shapes, wires and forgings.

| 1000 Series Alloy (Generally called commercial pure aluminum,AI>99.0%) | |

| Alloy | 1050 1050A1060 1070 1100 |

| Temper | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/H26/H36 H18/H28/H38 H114/H194, etc. |

| Specification | Thickness<30mm; Width<2600mm; Length<16000mm OR Coil (C) |

| Application | Lid Stock. Industrial Device, Storage. All Kinds of Containers, etc. |

| Feature | Lid Shigh conductivity, good corrosion resistant performance, high latent heatof melting, high-reflectance, well welding property*, low strength, and notsuitable for heat treatments. |

| 3000 Series Alloy (Generally called Al-Mn Alloy, Mn is used as main alloy element) | |

| Alloy | 3003 3004 3005 3102 3105 |

| Temper | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/H26/H36 H18/H28/H38 H114/H194, etc. |

| Specification | Thickness0mm; Width<2200mm Length<12000mm OR Coil (C) |

| Application | Decoration, heat-sink device, external walls, storage, sheets for construction, etc. |

| Feature | Good rust resistance, not suitable for heat treatments, good corrosion resistantperformance, well welding property, good plasticity, low strength but suitablefor cold working hardening |

| 5000 Series Alloy (Generally called Al-Mg Alloy, the Mg is used as main alloy element) | |

| Alloy | 5005 5052 5083 5086 5182 5754 5154 5454 5A05 5A06 |

| Temper | O/H111 H112 H116/H321 H12/H22/H32 H14/H24/H34H16/H26/H36 H18/H28/H38 H114/H194, etc. |

| Specification | Thickness<170mm; Width<2200mm ; Length<12000mm |

| Application | Marine Grade Plate, Ring-Pull Can End Stock, Ring-Pull Stock. AutomobileBody Sheets, Automobile Inside Board. The Protective Cover On Engine. |

| 6000 Series Alloy (Generally called Al-Mg-Si Alloy, the Mg and Si are used as main alloy elements ) | |

| Alloy | 6061 6063 6082 |

| Temper | O F, etc. |

| Specification | Thickness<170mm; Width<2200mm ; Length<12000mm |

| Application | Automotive, Aluminium For Aviation, Industrial Mould. Mechanical Components,Transport Ship. Semiconductor Equipments, etc |

First, the corrosion resistance of aluminum ingots is high, the density is high, and the casting process is superb. The aluminum ingots are widely used in many high-tech instruments, and the sales volume in the market will become larger and larger.

Second, the aluminum ingot has reached an advanced level in heat treatment technology, which will greatly help to improve the quality level. In the process of aluminum ingot processing, advanced casting technology and equipment have been used to complete it, so that its technical advantages will be more prominent in the process of extensive application.

Standard airworthy packaging, or customized according to customer needs. Ports: Qingdao Port, Shanghai Port, Tianjin Port

| Quantity(Tons) | 1 - 20 | 20 - 50 | 51 - 100 | >100 |

| Est. Time(days) | 3 | 7 | 15 | To be negotiated |

| Grade | Chemical Composition % | ||||||

| Al≥ | impurities ≤ | ||||||

| Si | Fe | Cu | Ga | Mg | Zn | ||

| Al99.9 | 99.90 | 0.50 | 0.07 | 0.005 | 0.02 | 0.01 | 0.025 |

| Al99.85 | 99.85 | 0.80 | 0.12 | 0.005 | 0.03 | 0.02 | 0.030 |

| Al99.7 | 99.70 | 0.10 | 0.20 | 0.010 | 0.03 | 0.02 | 0.030 |

| Al99.6 | 99.60 | 0.16 | 0.25 | 0.010 | 0.03 | 0.03 | 0.030 |

| Al99.5 | 99.50 | 0.22 | 0.30 | 0.020 | 0.03 | 0.05 | 0.050 |

| Al99.00 | 99.00 | 0.42 | 0.50 | 0.020 | 0.03 | 0.05 | 0.050 |